Are you going too fast?

- James Dean Designs

- November 29, 2023

- Blog, Uncategorized

- Speeds and feeds

- 0 Comments

Questions around feeds and speeds on CNC machines are very common but also harder to answer on smaller spindles.

As part of reviewing the lastest FoxAlien CNC machine the XE-Pro, I was doing a depth test where I run the same job multiple times but each time going a little deeper. In this scenario I was using a 1/4 Downcut bit at 1000mm/min, start at 0.5mm deep, then 1mm deep, 1.5mm, 2mm and so on with the final square being 4mm deep in one single pass.

Did it cut it? Yes, but does that mean it was successful?

A quick way to tell if you’re going too fast

If we take a closer look, what we can see is the deeper it gets, the more the corners start to bulge out.

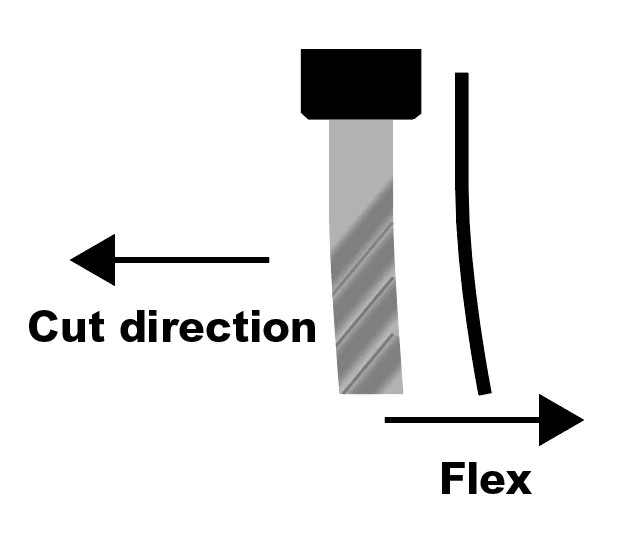

The reason for this is the bit and spindle shaft are flexing/bending as the material is being cut. When it slows down at the corner to change direction it essentially springs back a little in the opposite direction creating this shape.

So if you have these types of shapes in the corner of your cuts, then chances are it means your going too fast or too deep. You can slow the pass down, you can take a shallower cut or you can increase the RPM if that option is available to you.