UV and Fiber Lasers – Understanding the Differences Between Frequency and Q-pulse

- James Dean Designs

- January 11, 2025

- Uncategorized

- 0 Comments

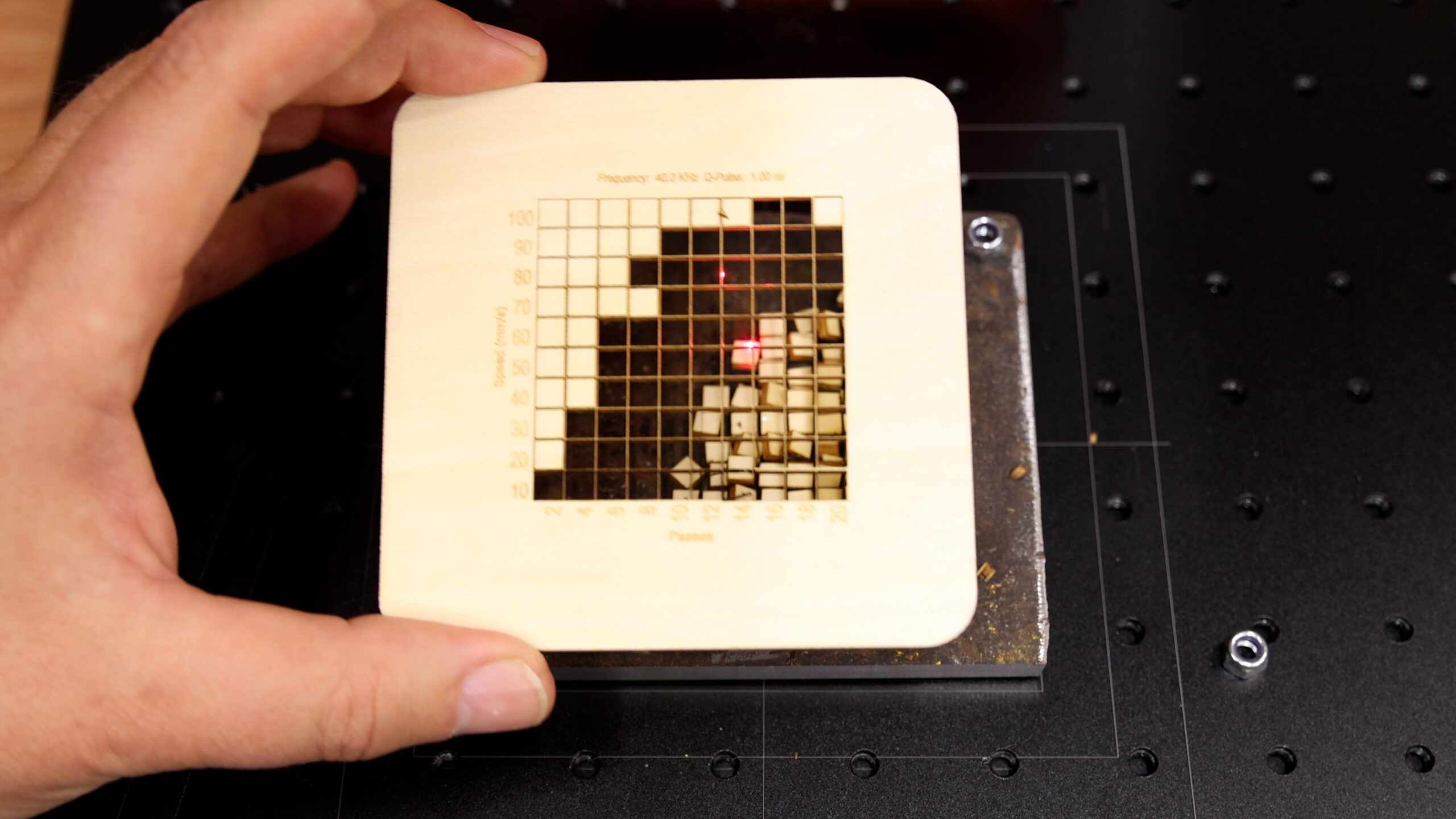

Over the past 8 months I have gone through a bit of a crash course with fiber lasers and UV lasers as part of my reviews ( 30w B4 Fiber – 60w B4 MOPA Fiber – 5w UV). One of the hardest things for people to understand is the settings so I wanted to talk about the differences between the Frequency and Q-pulse, how they both change the way the laser impacts your materials and the difference it will make increasing or decreasing both of them.

This article covers the following:

- The basics of each

- How adjusting the frequency will impact the material

- How adjusting the Q-Pulse setting will impact the material

- Adjusting Both the Frequency and Q-pulse Together

Lets start with a basic understanding of frequency:

Frequency:

- What it is: This refers to the number of wave oscillations (or cycles) that occur per second in the laser’s light.

- Measured in: Hertz (Hz), though in the context of light, we often talk about frequency indirectly via the wavelength (since they are inversely related).

- Relation to UV lasers: How many laser pulses are emitted per second. Adjusting this frequency directly affects how the laser’s energy is distributed over time and across the material.

Q-Pulse (Q-Switching):

- What it is: Q-switching is a technique used to produce pulsed laser output. Instead of emitting a continuous beam, the laser stores energy and then releases it in very short, powerful pulses.

- Measured in: Pulse repetition rate (Hz, how many pulses per second) and pulse duration (time of each pulse, often in nanoseconds or picoseconds).

- Relation to UV lasers: By controlling the Q-switch, the UV laser can deliver intense bursts of energy. This makes it highly effective for precision tasks like engraving, where high peak power is needed for a short time.

Key Differences:

In short: Frequency is about the light’s fundamental properties, while Q-pulse is about how that light is delivered.

How adjusting the frequency will impact the material

Low Frequency (Fewer Pulses per Second):

- Impact on Material:

- Higher Energy per Pulse: Each pulse contains more energy, which means more intense, concentrated impacts on the material.

- Deeper Marking or Cutting: Ideal for applications requiring deep engraving or cutting.

- Slower Process: Fewer pulses mean less material removal per second, so processing may take longer.

- Risk of Damage: Higher energy per pulse can sometimes lead to over-burning or micro-cracking, especially on delicate materials.

- Example Applications:

- Deep engraving.

- Cutting thicker materials.

- Processing hard or reflective surfaces like metals.

High Frequency (More Pulses per Second):

- Impact on Material:

- Lower Energy per Pulse: Energy is spread across more pulses, resulting in gentler impacts.

- Smoother, Finer Results: Better for precision work where excessive heat or damage must be avoided.

- Shallower Processing: Each pulse removes less material, which may limit the depth of marking or cutting.

- Faster Processing: The higher pulse rate can lead to faster overall material removal.

- Example Applications:

- Fine marking, like text or detailed patterns.

- Processing heat-sensitive materials, such as plastics.

- Avoiding discoloration or melting in softer materials.

Choosing the Right Frequency:

- Material Type:

- Hard materials (e.g., metals): Lower frequencies for deep marking or cutting.

- Soft materials (e.g., plastics): Higher frequencies for controlled, gentle processing.

- Desired Outcome:

- Depth: Use lower frequencies for deeper marks.

- Precision: Use higher frequencies for detailed, clean work.

- Thermal Effects:

- Higher frequencies generate more heat accumulation over time, which can impact the material differently depending on its heat tolerance.

By understanding these effects, you can optimize the frequency setting to achieve the desired results while minimizing unwanted side effects.

How adjusting the Q-Pulse setting will impact the material

When adjusting the Q-pulse setting (typically the pulse duration or Q-switch timing) of a UV laser, you’re controlling how energy is stored and released in each pulse. This adjustment affects the laser’s peak power, pulse width, and overall energy delivery, influencing how the material responds to the laser. Here’s how it impacts the material:

Longer Pulse Duration (Lower Peak Power):

- Impact on Material:

- Reduced Peak Power: Energy is delivered more gradually during each pulse.

- Less Aggressive Material Interaction: Suitable for delicate materials where too much energy might cause damage, such as warping, discoloration, or burning.

- Lower Depth or Penetration: Less intense pulses mean less energy to ablate or remove material.

- Smoother Finish: The longer, gentler pulse creates a more even energy distribution, reducing roughness.

- Example Applications:

- Marking or processing sensitive materials like thin plastics or coated surfaces.

- Applications requiring a smooth, polished finish.

Shorter Pulse Duration (Higher Peak Power):

- Impact on Material:

- Increased Peak Power: Energy is concentrated in a very short burst, creating more intense impacts on the material.

- More Aggressive Ablation: Ideal for quickly removing material, cutting, or engraving deeper into harder surfaces.

- Risk of Damage: The higher intensity can create micro-cracking, charring, or excess heat-affected zones, especially in sensitive or brittle materials.

- Higher Precision: The short, sharp pulses can minimize heat diffusion, making it suitable for applications requiring precision with minimal thermal damage.

- Example Applications:

- Deep engraving or cutting metals.

- High-speed marking of hard materials.

- Applications requiring sharp edges or minimal heat spread.

Key differences in results

| Aspect | Longer Pulse Duration | Shorter Pulse Duration |

| Energy per Pulse | Spread over a longer time | Concentrated in a brief burst |

| Material Removal | Slower and shallower | Faster and deeper |

| Thermal Effects | More heat spread, less intense | Localized heat, high peak power |

| Surface Finish | Smoother and polished | Potentially rougher or sharper |

Choosing the Right Q-Pulse Setting:

- Material Type:

- Soft or sensitive materials (e.g., plastics, fabrics): Longer pulses to avoid damage.

- Hard or reflective materials (e.g., metals, ceramics): Shorter pulses for effective ablation.

- Desired Outcome:

- Depth and speed: Shorter pulses for aggressive cutting or engraving.

- Precision and finish: Longer pulses for clean, polished results.

- Thermal Effects:

- Longer pulses spread heat more evenly but may affect larger areas.

- Shorter pulses minimize heat spread, focusing energy precisely where needed.

Adjusting the Q-pulse setting allows you to fine-tune the laser for specific applications, balancing speed, depth, precision, and thermal effects.

Adjusting Both the Frequency and Q-pulse Together

Adjusting Q-pulse and frequency together offers a powerful way to fine-tune a UV laser’s performance. By controlling both the energy delivered per pulse (via Q-pulse) and how frequently those pulses are emitted (via frequency), you can optimize the laser’s behavior for specific materials and applications. Here’s how the interaction works and its impact on the material:

Adjusting Q-pulse and frequency together offers a powerful way to fine-tune a UV laser’s performance. By controlling both the energy delivered per pulse (via Q-pulse) and how frequently those pulses are emitted (via frequency), you can optimize the laser’s behavior for specific materials and applications. Here’s how the interaction works and its impact on the material:

Interplay Between Q-Pulse and Frequency:

- Q-Pulse (Pulse Duration): Determines how much energy is released in a single pulse and how that energy is distributed over time.

- Shorter Q-pulse = Higher peak power, concentrated energy.

- Longer Q-pulse = Lower peak power, spread-out energy.

- Frequency (Pulse Repetition Rate): Controls how many pulses are delivered per second.

- Lower Frequency = Fewer pulses, more energy per pulse.

- Higher Frequency = More pulses, less energy per pulse.

Impact of Adjusting Both:

| Setting | Effect on Material |

| Short Q-Pulse + Low Frequency | High peak power and low pulse overlap. Excellent for deep engraving or cutting hard materials. Risk of damage or rough edges. |

| Short Q-Pulse + High Frequency | High peak power with frequent pulses. Provides faster processing with controlled depth but may accumulate heat. |

| Long Q-Pulse + Low Frequency | Gentle, deep pulses with minimal overlap. Suitable for processing brittle or delicate materials. |

| Long Q-Pulse + High Frequency | Smooth, shallow impacts with frequent overlaps. Ideal for fine marking or polishing. |

Detailed Scenarios:

- High Precision with Minimal Heat:

- Use short Q-pulse for focused energy.

- Combine with high frequency to distribute the energy over the surface.

- Result: Sharp, detailed marks with minimal thermal effects.

- Deep Engraving or Cutting:

- Use short Q-pulse for high peak power.

- Combine with low frequency to concentrate energy in fewer, powerful pulses.

- Result: Deeper material removal but may risk rougher edges.

- Smooth, Polished Finishes:

- Use long Q-pulse to reduce peak power and spread the energy.

- Combine with high frequency for even surface coverage.

- Result: Smooth marks or finishes, ideal for aesthetic applications.

- Delicate Material Processing:

- Use long Q-pulse to reduce the risk of cracking or burning.

- Combine with low frequency to avoid excessive heat accumulation.

- Result: Safe, controlled processing of fragile or heat-sensitive materials.

Balancing the Two Settings:

- Energy Per Pulse: Lower frequency increases energy per pulse, while higher frequency reduces it. Pair this with Q-pulse settings to control how intensely the energy interacts with the material.

- Processing Speed: Higher frequency generally means faster overall processing, but this can dilute the depth of individual impacts.

- Thermal Effects: Short Q-pulse minimizes heat spread, while long Q-pulse spreads heat more evenly. Adjust frequency to either concentrate (low) or dissipate (high) heat.

By carefully adjusting both Q-pulse and frequency together, you can tailor the laser’s output to achieve the desired combination of speed, depth, precision, and thermal control for your specific application.